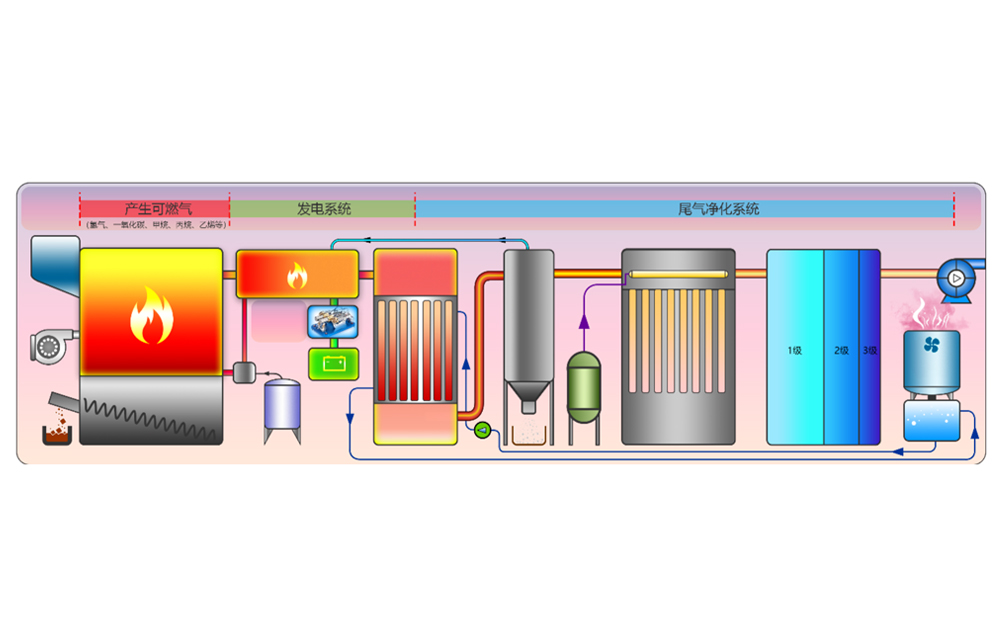

The industrial residual gas-to-energy process uses combustible gas generated from fuel combustion and production in industrial enterprises. The residual gas is fully burned through the combustion chamber of Apollo MeMs power generation system to generate electricity. Leveraging the characteristics of working gas expanding when heated and compressing when cooled, the generator converts external thermal energy into mechanical energy, thus driving the generator to rotate and generate green electricity.

This part of industrial residual gas contains combustible gas components (e.g. hydrogen, carbon monoxide, methane, propane, ethylene, etc.) produced in industrial production. Capable of using a wide range of fuel sources and tolerating a relatively high proportion of impurities in the fuel, the Apollo MeMs power generation system is applicable in many fields. The Apollo MeMs power generation system uses this part of industrial residual gas as fuel to generate electricity in its unique power generation chamber.

China has put forward the policy of energy structure adjustment to cater to the need of social development. By rationally utilizing the thermal energy of residual gas, the industrial residual gas-to-energy process can improve the energy utilization rate, reduce the loss and effectively save the use of industrial coal. The combustion chamber of the Apollo MeMs power generation system fully decomposes the combustible gas, significantly reducing the concentration of pollutants such as carbon dioxide and combustible organic matter, and complying with the discharge standards. The industrial residual gas-to-energy process integrates comprehensive utilization of resources, energy conservation and efficiency improvement, safety and environmental protection, thus featuring good economic and social benefits.